The type of TPS sensor we use here is called a Linear throttle position sensor or Pontentiometer type sensor. Potentiometer type sensors hold a variable resistor with a slide contact inside of them. As you push in the accelerator and the throttle butterfly moves, the contact changes its position on the variable resistor. As the throttle position changes the output voltage from the sensor changes. As the throttle opens (throttle position angle increases) the resistance is decreased, thus increasing the output voltage from the sensor:

15` - voltage is at 1.4v

30` - 2.1v

45` - 2.6v

60` - 3.1v

75` - 3.6v

90` - 4.7v

Idle puts out a low voltage (the least voltage) and this is how it is recognised. Usually about 0.4 - 100mV.

|

| TPS Readings |

Throttle Position Switch (TPS)

|

| TPS Readings |

From zero to fifteen degrees, the ohm reading is at 0.5ohm.

At fifteen degrees, the resistance shoots to an overload reading (O.L.).

As the angle increases, up to seventyfive degrees resistance stays in overload (O.L.). From seventyfive degrees the resistance is back in range, at 0.5ohm.

AIR FLOW SENSORS (MAF, MAP, THA, AFM, VAF)

The air flow sensor is located at the point of entry of air into the fuel injection system. The air flow sensor sends air volume, pressure and temperature information to the ECU. As intake manifold pressure is directly related to engine load, the ECU needs to know intake manifold pressure in order to calculate how much fuel to inject and when to ignite the air/fuel charge.

The air filter resides in the housing below the air flow sensor and must be routinely changed for continued quality of operation.

Vane Type Air Flow Meter (VAF)

A Vane type air flow meter measures air pressure/volume and air temperature seperately. Similar to a throttle position sensor in that the Vane type air flow meter uses a slide contact running along a variable resistor to get a variation in voltage outputs as load is applied.

There are two main types of VAF sensors. The first design, uses battery supply voltage. As the measuring plate opens, voltage is increased. The second design uses a regulated 5v input.

During Engine operation, intake air flow reacts against the measuring plate and its return spring, and deflects it in proportion to the volume of air flow passing the plate. A compensating plate, found in the dampening chamber acts as a shock absorber to prevent rapid movement or vibration of the slide contact attached.

|

| VAF Sensor Wiring Schematic |

Testing this sensor can be done with an ohm meter, testing individual cricuits for variable resistance in response to air vane movement.

However it is more accurate to test the the voltage output signal on the vehicle. By back probing the multi-plug with the ignition turned on.

|

| VAF Sensor Readings |

This photo shows the readings when tested off-car but hooked up to a power supply of only 5v and not battery voltage (12v). The graph shows the desired voltage output pattern of:

0' - 0.83v

20' - 2.7v

45' - 3.9v

60' - 4.3v

75' - 4.75v

90' - 5v

Manifold Absolute Pressure (MAP)

The MAP sensor measures the voltage difference between a reference resisted output and a varing output resisted as to the pressure in the intake manifold.

In the Map sensor there is a silicon chip mounted inside a reference chamber. On one side of the chip is a reference pressure, this reference pressure is at a calibrated pressure. On the other side is the pressure to be measured. The silicon chip changers its resistance depending on the changers of pressure, this change in resistance alters the voltage signal. The ECU interprets the voltage signal as pressure and any change in the voltage signal means there is a change in pressure.

High vacuum is low pressure, or less air coming in. Low vacuum is high pressure, or more air coming in. The more the throttle is held open, the more air comes in, the higher the MAP reading.

|

| Wiring Schematic of a MAP Sensor |

MAP sensors are tested using a mity-vac which applies pressure to the sensor. Hooking up the MAP sensor to a 5v voltage supply and to a mity-vac, the following readings are displayed:

|

| MAP Sensor Readings |

0 cmHg - 9.84v

10 cmHg - 4.16v

20 cmHg - 3.44v

30 cmHg - 2.75v

40 cmHg - 2.01v

50 cmHg - 1.31v

60 cmHg - 0.65v

70 cmHg - 0.06v

Air Flow Meter Hot Wire Type (MAF)

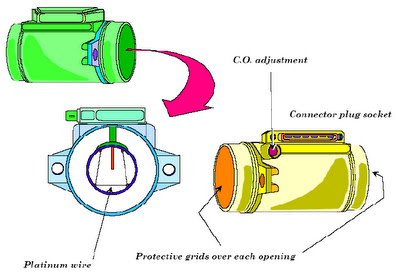

MAF sensors are the newest and most commonly used type of air flow measuring sensor. They consist of a thermistor, a platinum hot wire and an electronic control circuit.

The thermistor measures the temperature of the incoming air. The platinum hot wire stays at a constant temperature in relation to the thermistor by the control circuit.

An increase in air flow will cause the platinum hot wire to lose heat faster and the control circuit will compenstate by sending more current through the hot wire. The circuit simaltaneously measures the current flow and puts out voltage signal accordingly.

|

| MAF Sensor Diagram |

TEMPERATURE SENSORS (ECT, IAT)

The ECU uses different temperature measurments of the engine to adjust various systems (fuel injection, ignition timing). It is important that proper operating temperature is reached and properly signalled to the ECU, in order for these systems to operate effectively.

Coolant Temperature Sensor (ECT, THW)

The ECT sensor responds to change in the engine coolant temperature and signals the ECU accordingly. This type of sensor is a NTC thermistor which change their resistance depending apon the temperature.

Testing this sensor with an ohmmeter gives us readings as follows:

|

| Coolant Temp Sensor Readings |

35'C - 1.53 k/ohm

40'C - 1.46 k/ohm

45'C - 1.02 k/ohm

50'C - 0.89 k/ohm

60'C - 0.70 k/ohm

70'C - 0.522 k/ohm

75'C - 0.415 k/ohm

80'C - 0.345 k/ohm

Intake Air Temperature (IAT, THA)

The IAT sensor responds to change in the intake air temperature and signals the ECU accordingly. Most older vehicles have a seperate IAT sensor in the intake manifold. The mordern, more common systems have the Hot Wire type air flow meter which incorporates the IAT sensor in its internal operations.

The air temperature sensor is much like the coolant temp sensor, in that it is a NTC thermistor. They change their circuits resistance according to the temperature. Also an ohmeter is used to test the operations of the sensor, as follows:

|

| Intake Air Temp Sensor |

This graph shows the resistance readings as temperature increases. When coolant temperature is below 40'C the resistance reads over load, meaning no voltage signal will be recieved from the sensor. The graph shows a slight spike in the resistance decrease (voltage increase) curve. Readings as follows:

20'C - O.L.

30'C - O.L.

40'C - 1.2k/ohm

50'C - 0.8k/ohm

60'C - 0.5k/ohm

70'C - 0.41k/ohm

80'C - 0.34k/ohm

90'C - 0.24k/ohm

100'C - 0.22k/ohm

Thermo Fan Switch

The thermo fan switch contains a bi-metal strip that has two different metal types fused together. They both have different expanding rates when the same amount of heat is applied. This means one side of the strip will expand sooner than the other side, causing it to bend in the direction of the side in which the metal does not expand as early.

In light of this, if the metal strip was touching the contact which switched it to ground, it would flex and the contact would disconnect from the strip. Or, if the strip was not touching the contact, the metal strip will flex and come into contact with the earth switching contact. Thermo switchs come as 'normally on' or 'normally off'.

|

| Thermo Fan Switch Readings |

As you can see the contact in this thermo switch is 'normally off'. It will read over load up until about 95'C (depending on specs) then it will switch to ground and have a reading of 0.3ohms.

No comments:

Post a Comment